Product Classification

Products

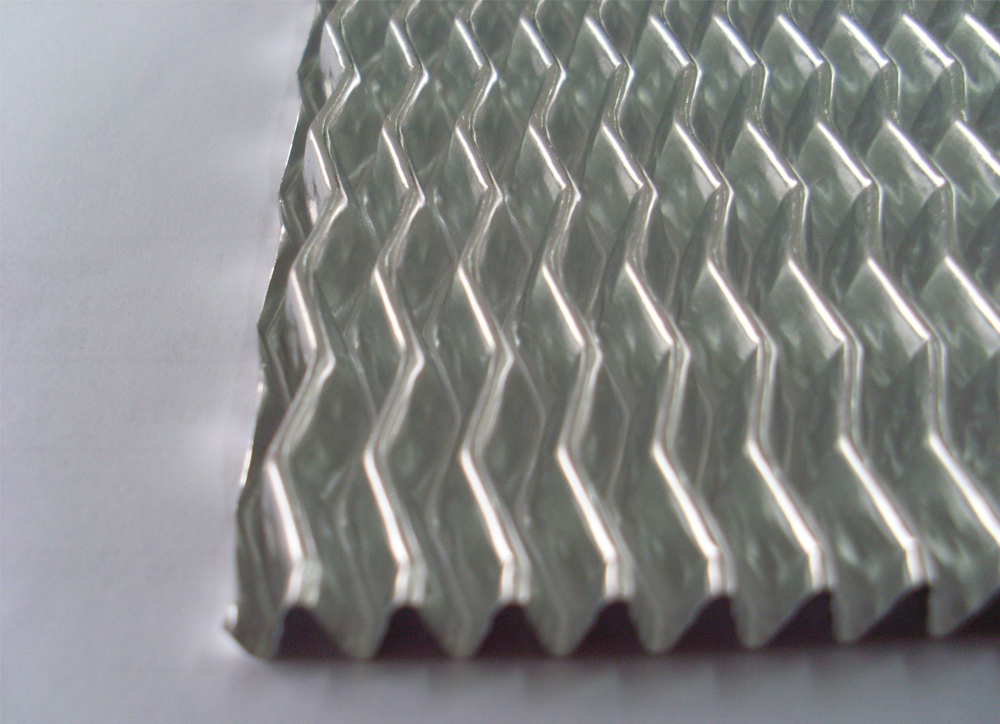

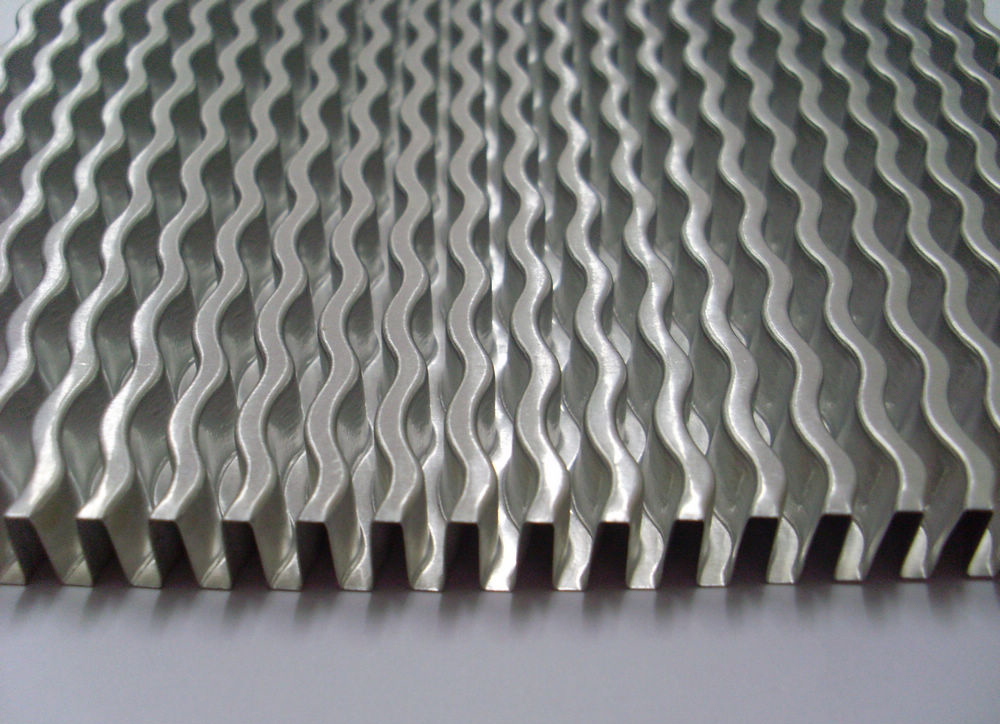

fin

An aluminum fin in a plate fin heat exchanger is a critical component designed to enhance heat transfer efficiency in the system. Plate fin heat exchangers are commonly used in various applications, including HVAC systems, aerospace, automotive cooling, and industrial processes. They are known for their compact design and high-performance capabilities.

Product details

An aluminum fin in a plate fin heat exchanger is a critical component designed to enhance heat transfer efficiency in the system. Plate fin heat exchangers are commonly used in various applications, including HVAC systems, aerospace, automotive cooling, and industrial processes. They are known for their compact design and high-performance capabilities.

Here's an introduction to the aluminum fin within a plate fin heat exchanger:

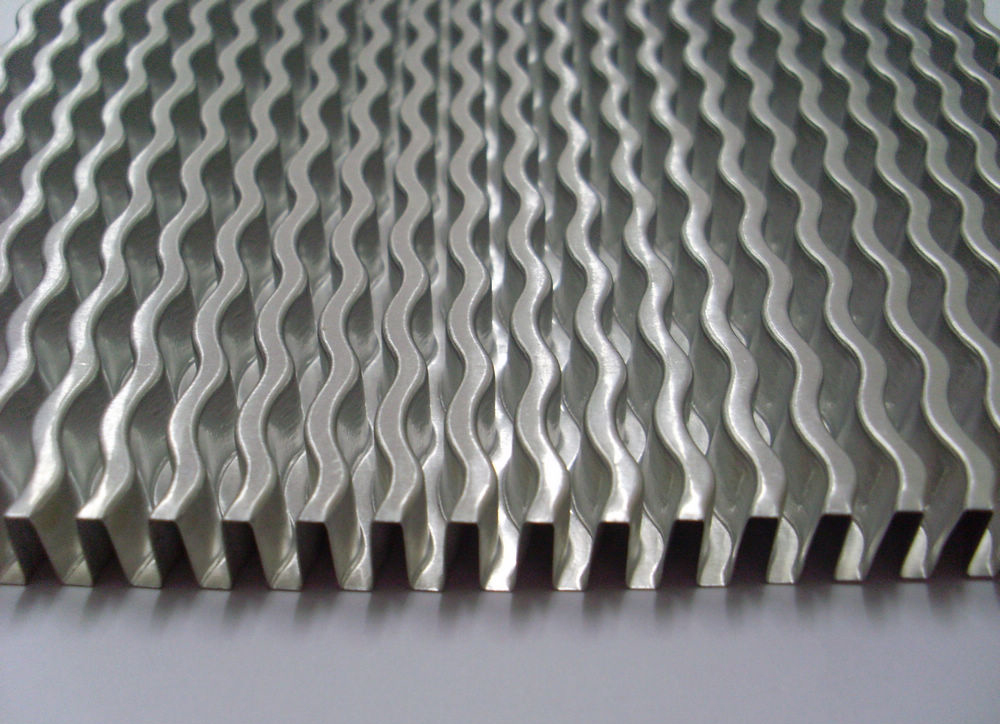

1. Purpose: The primary purpose of aluminum fins in a plate fin heat exchanger is to increase the heat transfer surface area. These thin, corrugated aluminum sheets are attached to the heat exchanger tubes or channels. By extending the surface area, they facilitate the exchange of heat between two fluids that flow on either side of the fins.

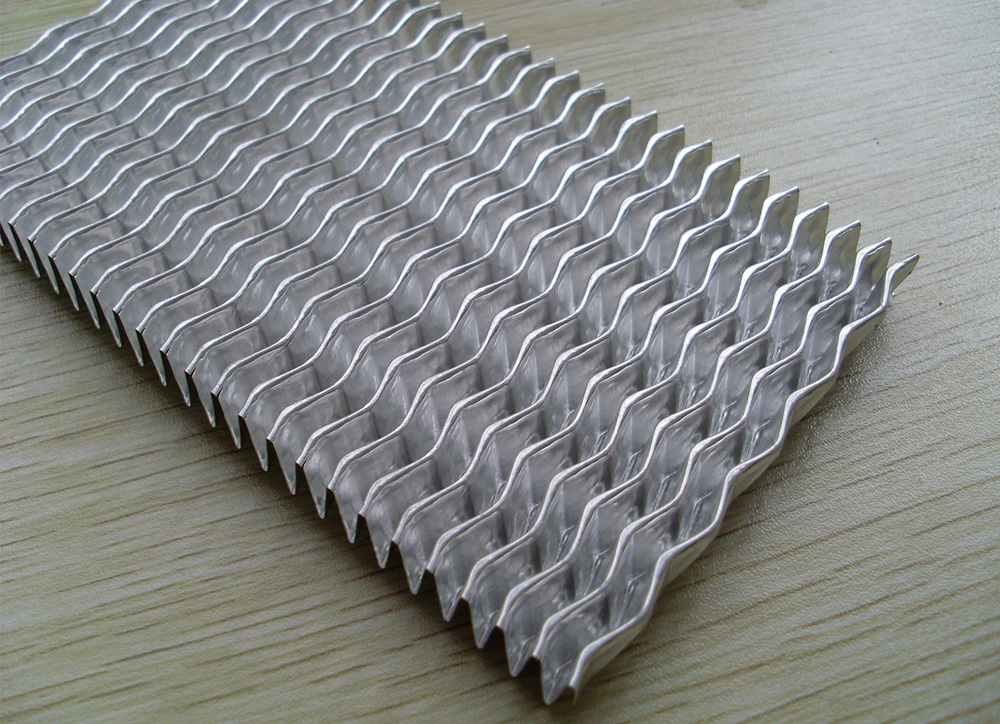

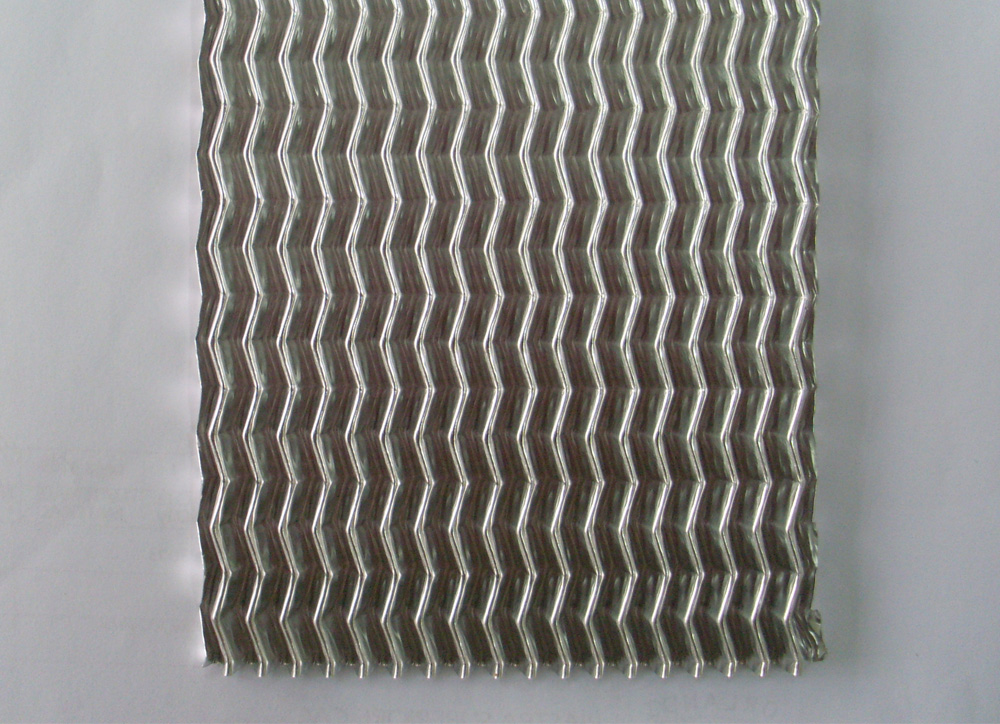

2. Construction: Aluminum fins are typically made of high-purity aluminum to ensure good thermal conductivity. They are corrugated or serrated to create turbulence in the airflow or fluid flow, which enhances heat transfer. The corrugations also add rigidity to the fins, making them more durable.

3. Arrangement: In plate fin heat exchangers, aluminum fins are usually stacked in a compact manner between two separator plates. These fins create multiple flow channels for the hot and cold fluids. The arrangement can vary in terms of fin density, height, and width, depending on the specific heat exchanger design and application.

4. Heat Transfer: As hot fluid flows over one side of the fin, and cold fluid flows over the other side, heat is transferred from one to the other through the thin aluminum fins. The corrugated structure of the fins disrupts laminar flow, promoting turbulence, which, in turn, increases the heat transfer coefficient.

5. Efficiency: Aluminum fins are known for their high thermal conductivity, making them an excellent choice for heat exchanger applications. They are lightweight and provide a cost-effective solution for improving the efficiency of the heat exchange process.

6. Maintenance: While aluminum fins are efficient, they can be susceptible to corrosion, particularly in certain environments. Proper maintenance and, if necessary, the use of protective coatings or alloys can mitigate this issue.

7. Applications: Plate fin heat exchangers with aluminum fins are used in a wide range of industries, including air conditioning and refrigeration, aerospace for aircraft engine cooling, and in the automotive industry for engine oil coolers and transmission fluid coolers.

In summary, aluminum fins in a plate fin heat exchanger play a crucial role in enhancing heat transfer efficiency by increasing the surface area available for heat exchange. Their design and material properties make them a popular choice in various industries where efficient heat exchange is a critical requirement.