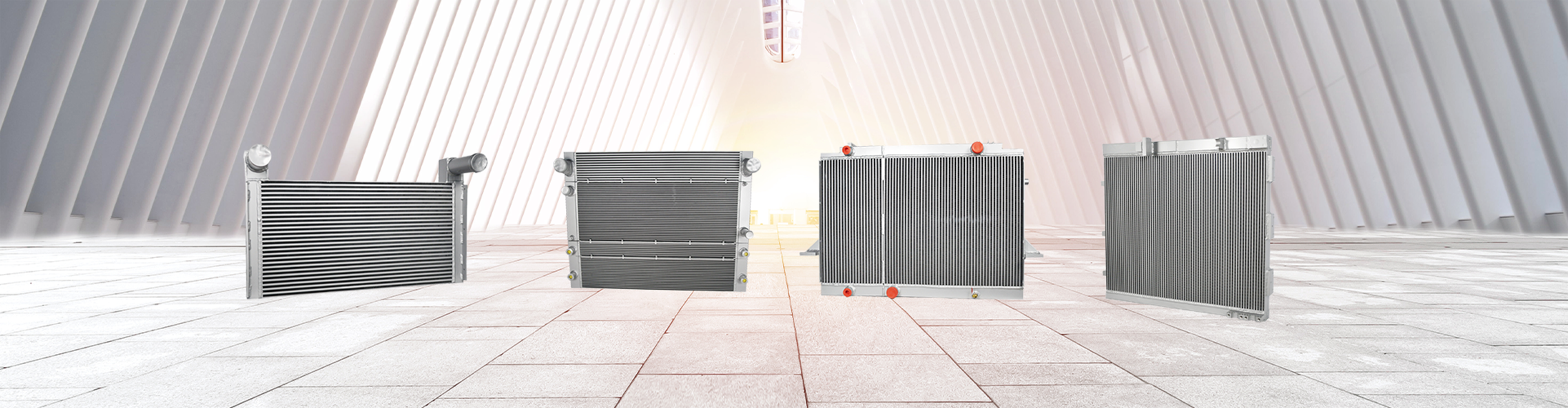

Product Classification

Products

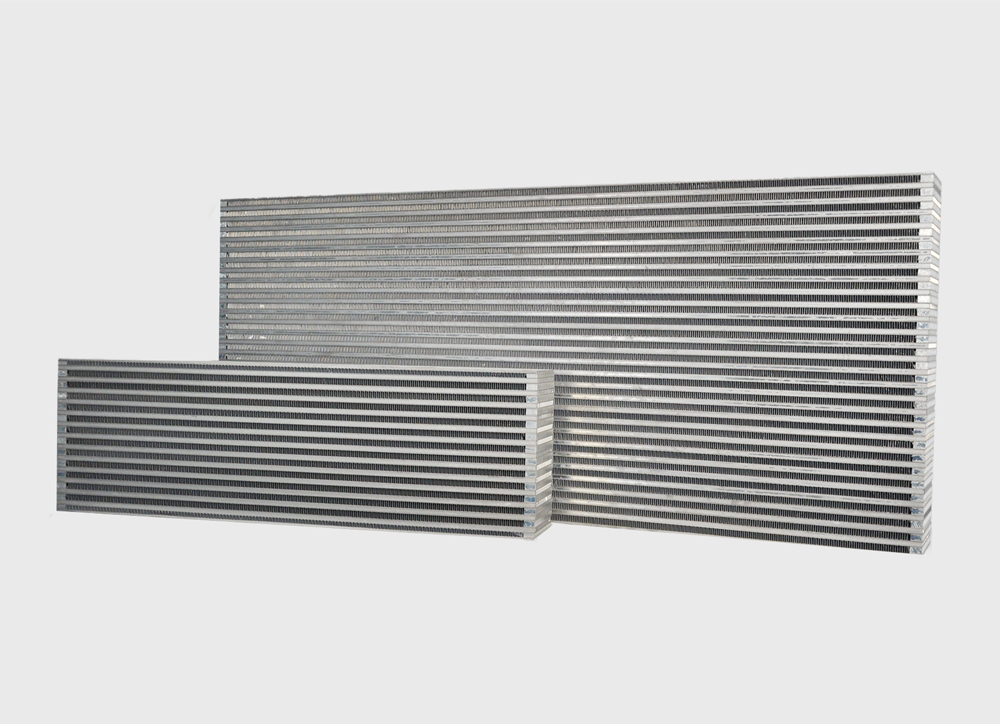

core

Product details

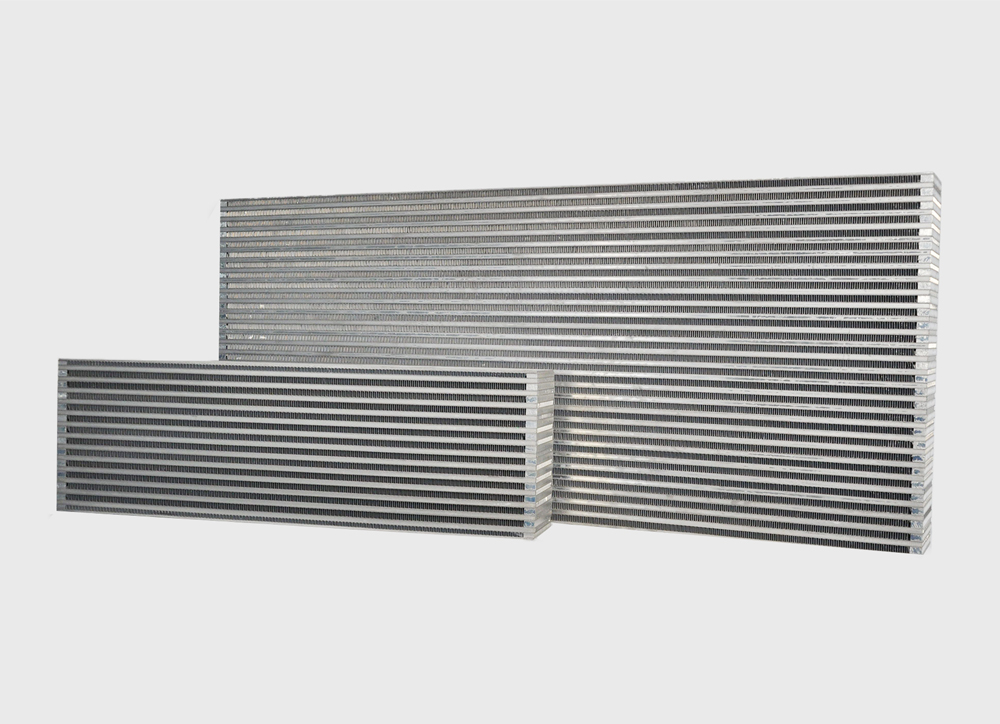

An aluminum plate fin core is a critical component found in heat exchangers, particularly in applications where efficient heat transfer and compact design are essential. This type of core is commonly used in radiators, intercoolers, and oil coolers, among other applications. Here's an introduction to the aluminum plate fin core:

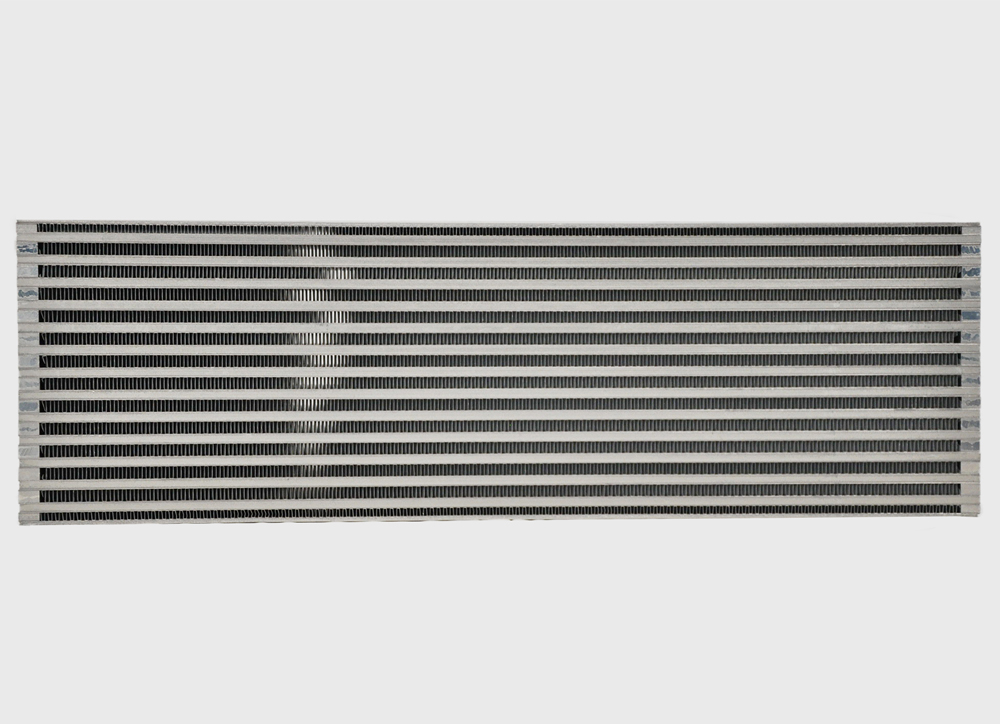

1. Purpose: The primary purpose of an aluminum plate fin core is to facilitate heat exchange between two fluids. It consists of a series of flat, thin aluminum plates (fins) stacked closely together to create a highly efficient heat transfer surface. The core allows for the transfer of heat from one fluid (such as coolant or air) to another (such as engine coolant or oil).

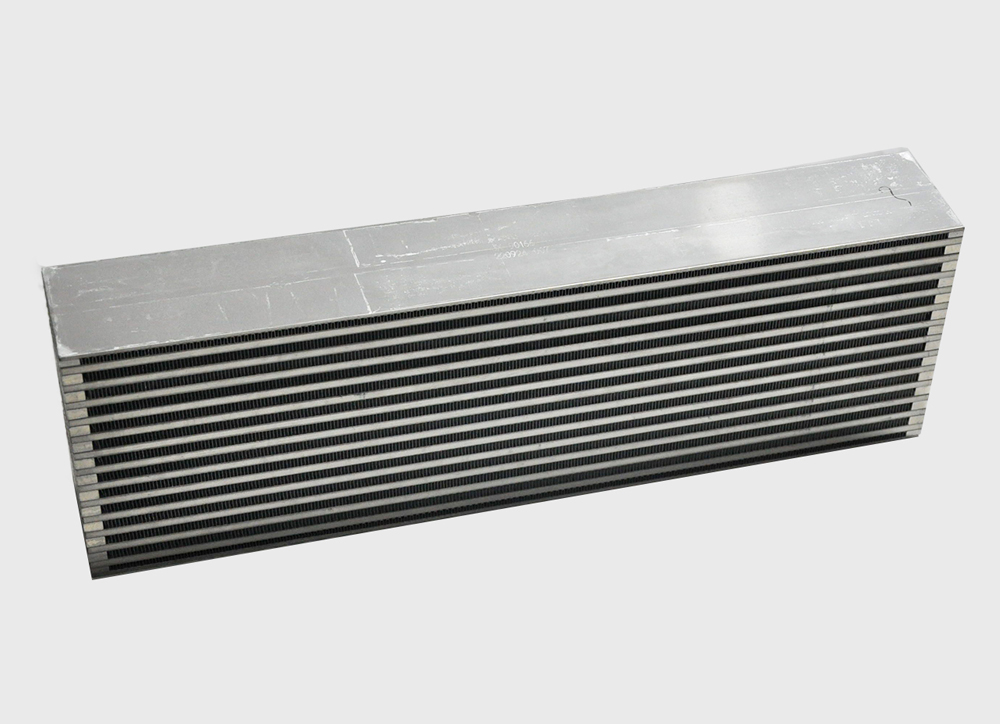

2. Construction: An aluminum plate fin core is composed of multiple parallel plates, typically made of high-quality aluminum or aluminum alloys. These plates are precisely spaced and attached to headers or tanks at the ends to create fluid passages. The fins are typically corrugated or serrated to increase the turbulence of the fluid flow and, in turn, enhance heat transfer.

3. Arrangement: The plates and fins in the core are aligned in a manner that creates a matrix of passages through which the fluids flow. The arrangement can vary in terms of fin density, thickness, and orientation, depending on the specific heat exchanger design and intended application.

4. Heat Transfer: Aluminum plate fin cores are designed to promote efficient heat transfer. As one fluid, usually air, flows over the exterior surface of the fins, and another fluid flows through the passages between the fins, heat is transferred from one fluid to the other. The fin arrangement disrupts laminar flow, promoting turbulence, which significantly improves the heat transfer coefficient.

5. Efficiency: Aluminum plate fin cores are known for their high thermal conductivity, which makes them an ideal choice for applications that require rapid and efficient heat exchange. Their compact design and lightweight nature further enhance their efficiency.

6. Durability: These cores are durable and can withstand a range of temperatures and pressures. However, they may be susceptible to corrosion in certain environments. Protective coatings or the use of corrosion-resistant alloys can mitigate this issue.

7. Applications: Aluminum plate fin cores are widely used in various indust

ries, including automotive cooling systems (radiators and intercoolers), industrial equipment and aerospace applications (aircraft heat exchangers), among others. Their compact design makes them particularly suitable for applications with space constraints.

An aluminum plate fin core is a crucial component in heat exchangers, designed to optimize heat transfer between fluids. Its high thermal conductivity, efficient design, and versatility make it a popular choice in a range of industries where efficient heat exchange is essential.

- Previous:radiator

- Next:cooling package