Product Classification

Products

cooling package

Product details

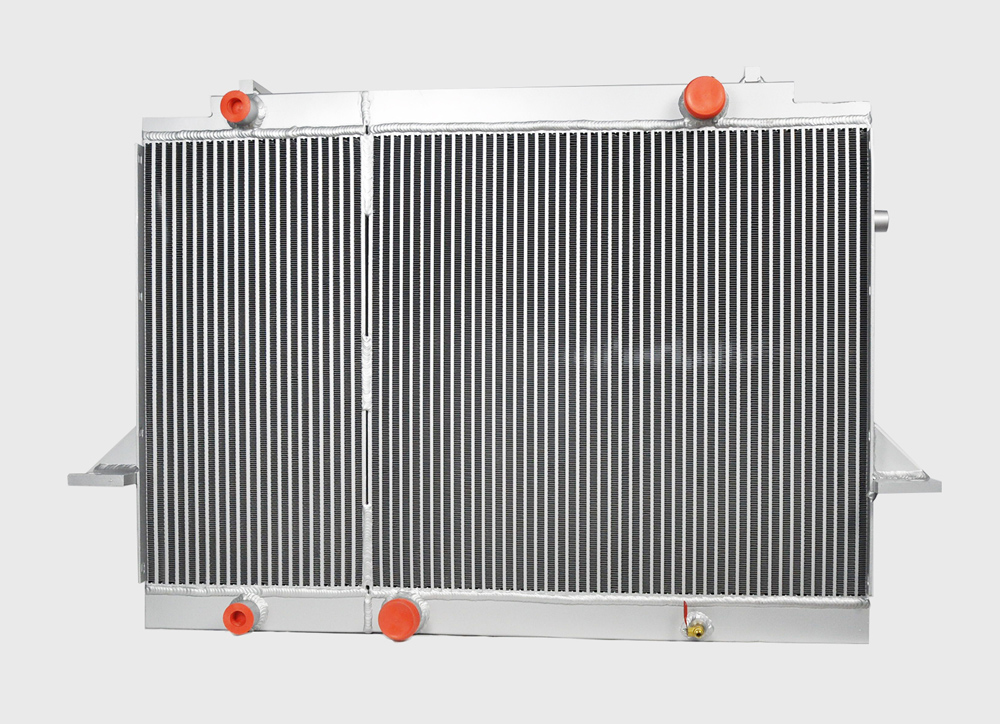

An aluminum plate fin cooling package is a specialized heat exchange system designed for efficient thermal management in a wide range of industrial and commercial applications. This cooling package utilizes a combination of aluminum plates and fins to effectively dissipate heat generated by various processes and equipment.

Aluminum plate fin cooling packages are a fundamental component of modern engineering and technology, addressing the critical need to maintain optimal operating temperatures for electronic devices, engines, power generation systems, and other heat-producing equipment. These packages are designed to facilitate the transfer of heat from a heat source to the surrounding environment, ensuring efficient cooling and preventing overheating-related damage.

Key Components:

· Aluminum Plates: The core of the cooling package consists of aluminum plates. These plates are chosen for their excellent thermal conductivity, lightweight properties, and corrosion resistance. They serve as the primary heat exchangers in the system.

· Fins: The aluminum plates are equipped with a series of closely spaced, thin fins. These fins significantly increase the surface area available for heat transfer, allowing for more effective cooling. The fin design can vary, but the concept remains consistent – maximizing the contact area between the heat source and the cooling medium.

· Fluid Pathways: Depending on the application, the cooling package may employ different fluid pathways. For air cooling, these pathways facilitate the circulation of air over the finned surfaces. In liquid cooling, channels are incorporated to carry a coolant (usually water or a specialized heat transfer fluid) to remove heat from the plates and fins.

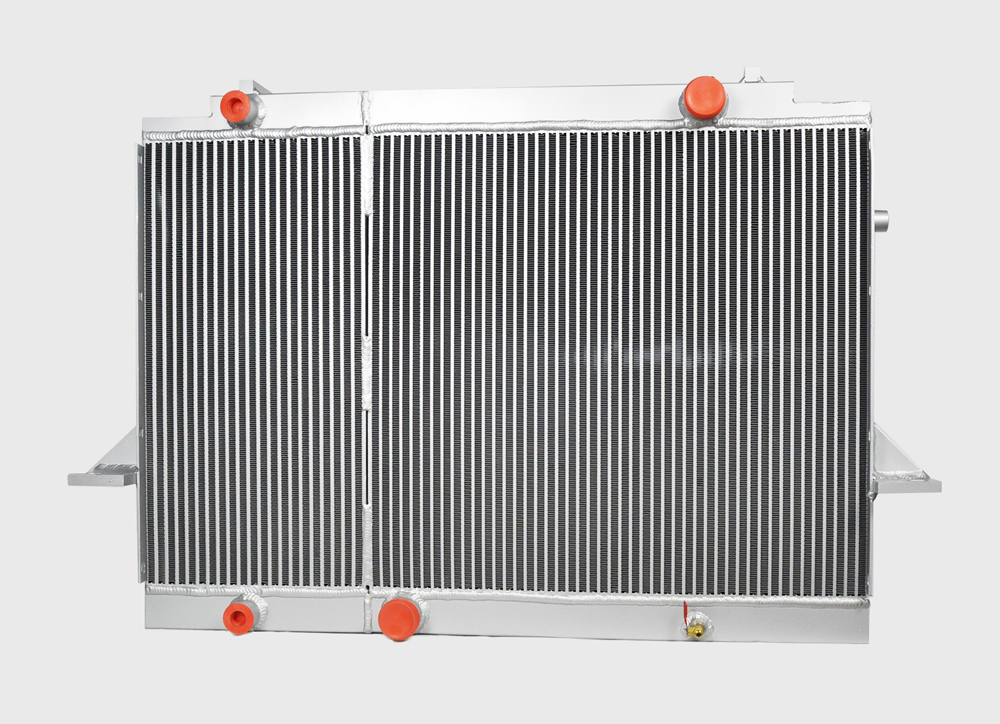

Key Features:

· Efficiency: Aluminum plate fin cooling packages are highly efficient at heat dissipation due to the increased surface area provided by the finned design. This promotes effective cooling, making them ideal for applications where temperature control is critical.

· Lightweight: The use of aluminum makes these cooling packages lightweight, which is particularly advantageous in industries where weight restrictions are a concern, such as aviation and automotive.

· Compact Design: The compact design of these packages allows for high heat dissipation rates in confined spaces, making them suitable for various applications where space is limited.

· Versatility: Aluminum plate fin cooling packages are versatile and adaptable, finding use in a wide array of industries, including electronics, automotive, aerospace, power generation, and more.

Applications:

· Electronics: In the electronics industry, these cooling packages are utilized to manage heat generated by components like CPUs, GPUs, and power electronics, ensuring stable and reliable operation.

· Automotive: In the automotive sector, they play a crucial role in engine cooling, transmission cooling, and air conditioning systems, enhancing vehicle performance and longevity.

· Aerospace: Aluminum plate fin cooling packages are vital in aircraft and spacecraft for effectively managing the heat generated by onboard systems and equipment, safeguarding against overheating in extreme conditions.

Advantages:

· High Heat Dissipation: The primary advantage of these cooling packages is their ability to efficiently dissipate heat, preventing equipment overheating and potential damage.

· Durability: Aluminum is known for its corrosion resistance, making it a durable choice for long-term use.

· Space-Saving: The compact design conserves space, making it suitable for applications where real estate is at a premium.

· Cost-Effective: The cost-efficiency of aluminum plate fin cooling packages, combined with their energy-saving capabilities, positions them as an attractive choice for many industries.

In conclusion, aluminum plate fin cooling packages are indispensable tools in modern engineering, ensuring the reliable and efficient operation of various systems and equipment. Their versatility, effectiveness, and ability to adapt to diverse applications make them a cornerstone of heat management in today's technology-driven world.

- Previous:core

- Next:Charge air cooler